At Wasthy, we believe that plastic pyrolysis, coupled with catalytic reforming and water-gas shift stages, can transform a major urban challenge—non-recyclable plastic waste—into a strategic energy vector: renewable hydrogen. The World Economic Forum (WEF) already highlights that decarbonizing plastics requires integrating clean hydrogen and chemical recycling, not just mechanical recycling. This is a clear signal of where the value chain must evolve if we are to meet net-zero goals.

The Science Behind Our Solution

Science backs this up. Recent literature shows that pyrolysis followed by in-line steam reforming (P-OSR) achieves high selectivity for H₂ from complex plastic mixtures. By optimizing temperature, steam/feed ratio, and catalysts (Ni, Fe, Ce), these processes maximize yields and minimize coke formation. These studies indicate that the bottleneck is no longer technical, but rather about scaling deployment and integrating with existing infrastructure.

Leading universities are also exploring low-energy complementary routes, such as solar-assisted photoconversion of PET and other polymers into hydrogen and value-added chemicals under mild conditions. Research groups at Cambridge and Swansea have published advances that, while still pre-commercial, broaden the frontier of technological options for different regulatory and energy-cost contexts.

The Path to Scalability

Is this scalable? Meta-analyses and reviews from 2024–2025 suggest that with temperatures around 900–1000 °C and suitable catalysts, hydrogen yields can be increased even in mixed waste streams (PET, PS, PP, etc.). The challenge lies in thermal balance, CO₂ capture/use from reforming, and competitive-cost PSA/MBR purification schemes. This is where process engineering and modular design—the Wasthy “Loop” approach—make a difference in CAPEX per ton and plant factor.

A Broader Market Vision

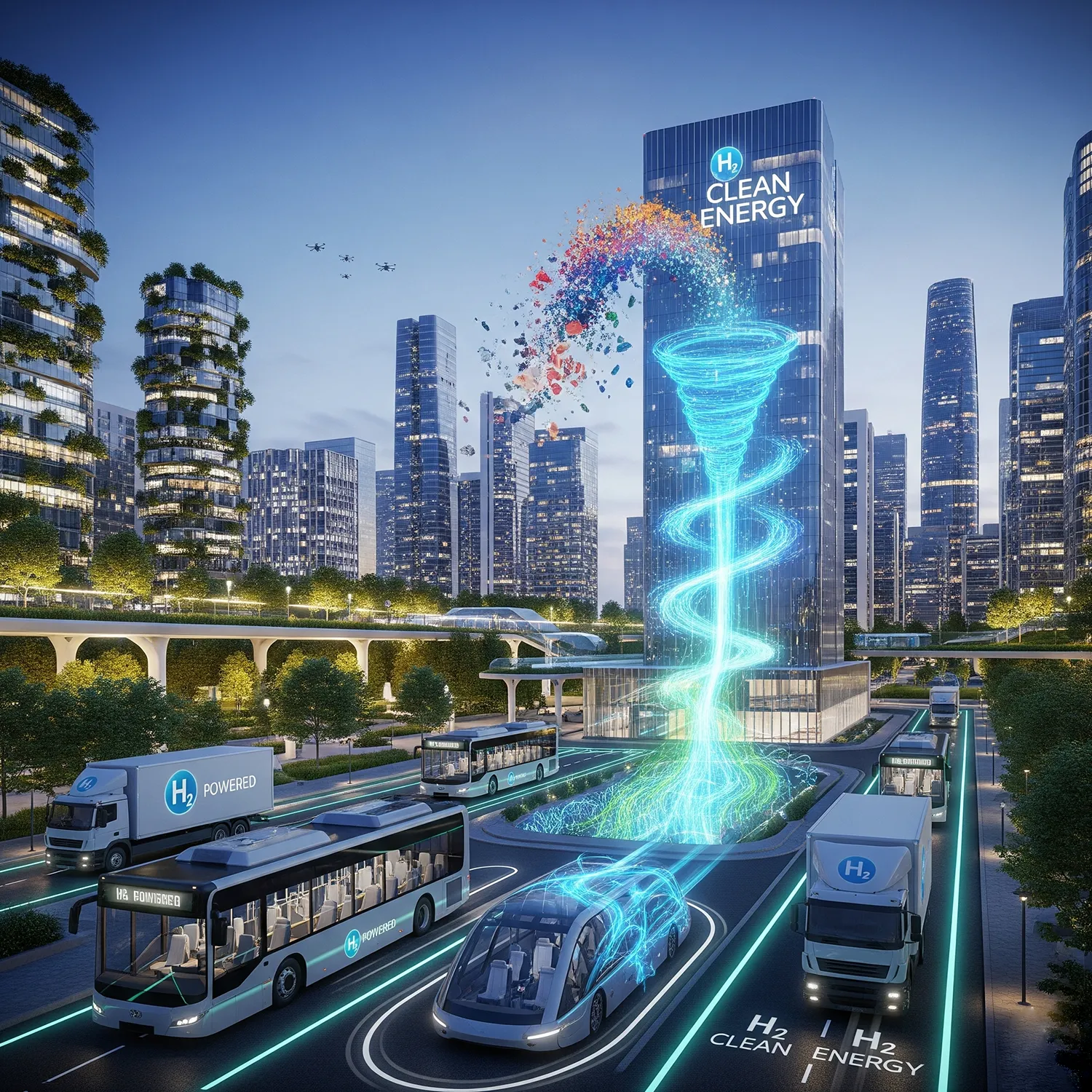

In parallel, the WEF underscores that green hydrogen is “the last mile” for net-zero in hard-to-abate sectors, though costs must still come down. Our thesis is that “green by electrons” (electrolysis) and “green by circularity” (plastic-to-H₂ with capture) are not competitors—they complement one another depending on local resources and energy prices.

Industry Perspective and Wasthy’s Pragmatic Approach

What do major operators think? Air Liquide and Linde promote a circular hydrogen economy vision: long-term industrial contracts, integration with SAF, and carbon capture in advanced reforming. This narrative validates that the market prioritizes decarbonized molecules and reliable logistics chains, beyond the “color” of H₂.

On the waste-to-H₂ front, players like SGH2 are betting on plasma gasification of waste (including plastics), digitalizing operations for efficiency and traceability. We share the same diagnosis: there is room for multiple pathways, and the key is the delivered LCOH, the real footprint (CO₂e/kg H₂), and compatibility with municipal permits.

Wasthy’s vision is pragmatic: we design modular plants that integrate pyrolysis + reforming + capture, validated by operational data and supply contracts with cities and ports. By converting a problematic waste stream into hydrogen and co-products (solid carbons or chemical intermediates), we help decarbonize heavy mobility and industrial heat without waiting for perfect electricity grids. The transition needs electrons… and circular molecules.